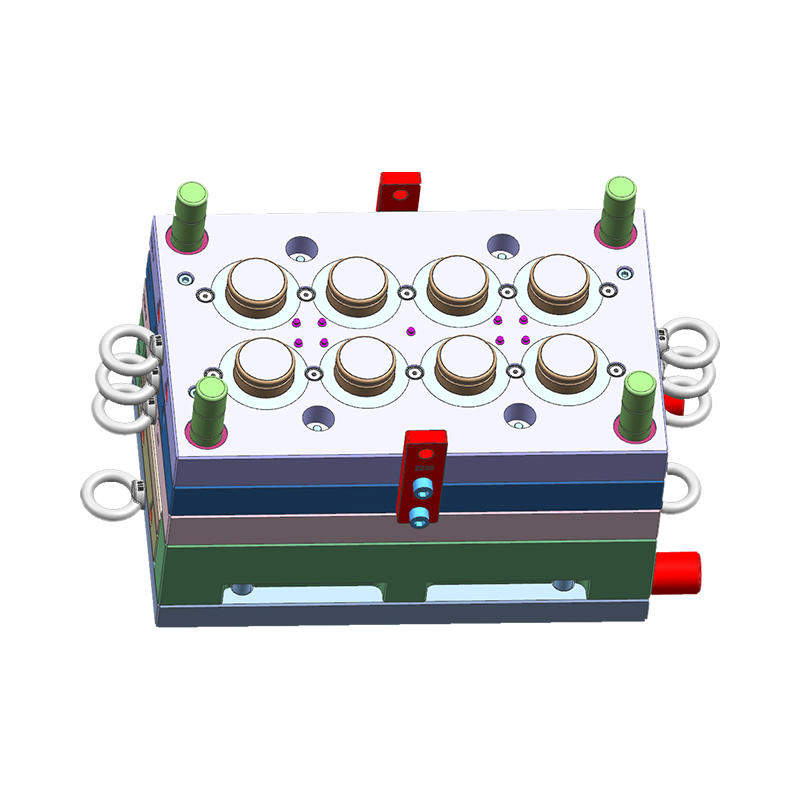

Supply Professional bottle cap mould Factory

Packaging plays a crucial role in product presentation and preservation, and the bottle cap is a vital component of any liquid container. Choosing the right Professional bottle cap mould is a decision that directly impacts the efficiency, safety, and aesthetic appeal of your packaging. In this guide, we will explore the key factors to consider when selecting a Professional bottle cap mould to meet your unique packaging needs.

Material Selection:

The step in choosing a bottle cap mould is to consider the material. Professional bottle cap moulds are commonly made from materials like steel and aluminium. Each material has its own set of advantages and disadvantages. Steel moulds are durable and long-lasting, making them suitable for high-volume production. On the other hand, aluminium moulds are lightweight and offer faster cooling times, which can be beneficial for certain applications. Evaluate the specific requirements of your packaging to determine the suitable material for your Professional bottle cap mould.

Mould Design and Complexity:

The design of the Professional bottle cap mould is a critical aspect that directly influences the final product. Consider the complexity of the cap design required for your packaging needs. Some molds are simple and cost-effective, suitable for standard caps, while others are intricate and designed for unique or custom shapes. Assess the design capabilities of the Professional bottle cap mould to ensure it aligns with your packaging requirements.

Production Volume:

The production volume is a significant factor when choosing a Professional bottle cap mould. Different moulds are designed to handle varying production capacities. If your packaging demands high-volume production, opt for a mould that can withstand continuous use without compromising on quality. Conversely, for smaller production runs, a mould with a lower cycle time may be more suitable. Matching the production volume to the capabilities of the bottle cap mould ensures efficiency and cost-effectiveness.

Compatibility with Bottle Type:

Not all bottle cap moulds are universally compatible with all types of bottles. Consider the specific characteristics of your bottles, such as size, shape, and neck diameter, and ensure that the chosen mould is compatible. A well-matched Professional bottle cap mould will contribute to a seamless and secure fit, preventing leaks and ensuring the overall integrity of the packaging.

Quality and Durability:

Investing in a high-quality bottle cap mould is essential for long-term success in packaging. Durability and robustness are key factors to consider, as they directly impact the lifespan of the mould and the consistency of the produced caps. Assess the quality standards of the manufacturer and the materials used to ensure that the Professional bottle cap mould can withstand the rigors of production over an extended period.

Cost Considerations:

While quality is paramount, cost is a practical consideration that cannot be overlooked. Evaluate the overall cost of the bottle cap mould, taking into account not only the initial investment but also factors such as maintenance, energy consumption, and operational efficiency. Striking the right balance between quality and cost ensures a cost-effective solution that meets your packaging needs.

Cooling System:

The cooling system of a Professional bottle cap mould is a critical component that affects the production cycle time and the quality of the caps. Efficient cooling is essential to achieve consistent and high-quality results. Evaluate the cooling system of the mould, considering factors such as cooling channel design and the type of cooling media used. An optimized cooling system contributes to faster cycle times and improved production efficiency.

Customization Options:

If your packaging requires unique or customized bottle caps, choose a mould that offers customization options. Some bottle cap moulds allow for interchangeable inserts or cavities, enabling the production of caps with different designs or functionalities. The ability to customize the caps adds versatility to your packaging, catering to specific market demands and enhancing the overall appeal of your products.

Manufacturer Reputation:

The reputation of the Professional bottle cap mould manufacturer is a crucial consideration in the selection process. Research the manufacturer's track record, customer reviews, and industry reputation. A reliable and experienced manufacturer is more likely to provide high-quality moulds that meet industry standards. Additionally, a reputable manufacturer often offers excellent customer support, including assistance with troubleshooting and maintenance.

Regulatory Compliance:

Ensure that the chosen bottle cap mould complies with relevant industry regulations and standards. Meeting regulatory requirements is essential for ensuring the safety and integrity of your packaged products. Check if the manufacturer adheres to international quality standards and has the necessary certifications. Regulatory compliance is particularly crucial in industries such as pharmaceuticals and food, where strict quality and safety standards are enforced.

In conclusion, selecting the right Professional bottle cap mould for your packaging needs is a strategic decision that involves careful consideration of various factors. The material, design, production volume, compatibility, quality, cost, cooling system, customization options, manufacturer reputation, and regulatory compliance are all critical aspects that contribute to the overall success of your packaging endeavors. By meticulously evaluating these factors, you can make an informed decision that aligns with your specific requirements, ensuring the seamless production of high-quality bottle caps for your packaging needs.

English

English русский

русский Español

Español عربى

عربى

+86-15157625901 / 13706572756

+86-15157625901 / 13706572756 info@suncomold.com

info@suncomold.com  No.2 Gongxin Avenue, Beicheng Street, Huangyan, Taizhou, Zhejiang, China

No.2 Gongxin Avenue, Beicheng Street, Huangyan, Taizhou, Zhejiang, China