The use scale of PET preform molds

In the production of PET bottle preform need to use his material, although the finished bottle preforms are relatively strong and durable, water and fire resistance are relatively good, but his material is relatively weak after comparison, then in the use of how to save his material? Let's take a look at it.

1, pay attention to the degree of humidity: in the case of pet bottle blanks for preservation of information to the right medicine, why say so? The requirements for the humidity of the different materials are different, the powder is definitely dry, and the granular is slightly lower than his, but their requirements for the humidity are relatively high.

2, pay attention to fire prevention: in the use of the time it is also very important fire prevention, plastic material we all know is not only more flammable and burning will be more dense black smoke, and to quell these flames will become more difficult, so to save time to save words, fire prevention is certainly the most important.

The good PET bottle preform is definitely inseparable from the good raw material, so at this point we look at the quality of the raw material and the preservation of the requirements of the pipe is definitely very good.

Now, the use scale of the bottle preform mold is more widespread, its energy-saving, long service life and other characteristics, so more and more production manufacturers love it. So what are the factors that affect the molding of bottle blast molds? Let's deepen our understanding.

First, the polymer in the extrusion machine conveying, melting, mixing, pumping out molding for the formation stage of the preform; in this stage, the factors that affect the wall thickness distribution are.

1, the molecular weight distribution of the material and the average molecular weight.

2, the temperature control system of the blow molding machine and screw speed, the temperature control system contains the hopper temperature, the temperature of the barrel 1 zone, 2 zone, 3 zone, 4 zone, the flange temperature and the temperature of the storage die head 1 zone, 2 zone, 3 zone, 4 zone.

Secondly, the stage of extrusion of the profile from the gap between the die lip and the die core is called the downfeed stage. At this time, the common phenomenon is the preform from the mold expansion and preform draping. The elements affecting these two phenomena are: the die diameter of the blow molding machine and the wall thickness control system, in which the control system contains the axial wall thickness control system, circumferential wall thickness control system, which is used to adjust the gap between the cavity and the core.

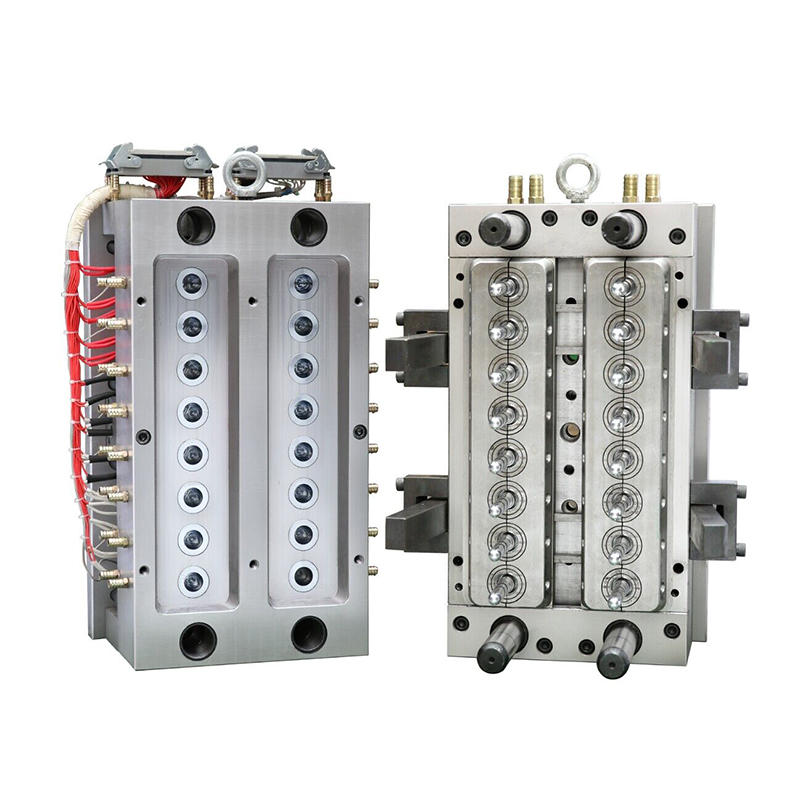

16 Cavity Short Tail PET Preform Mould

| Product Name | 16cavity Short Tail PET Preform mould |

| Core &Cavity Steel | S136,FS636,632 (Chinese Steel) ASSAB S136(Sweden) |

| Mould base | P20,4Cr13, Standard Mould Base |

| Steel hardness: | HRC32-35 for slider and stripper plate and other plates |

| HRC49-51 for core and cavity material. | |

| HRC49-51 for Neck ring and Lock ring | |

| Plastic material | PET resin |

| Cavity Number | 1x8, 1x12,1x16, |

| Injection System | Short tail |

| Ejector System | Stripper plate |

| Cycle Time | Based on preform weight |

| Delivery Time | 45-60 Days |

| Mould lifetime | At least 3 million Shots |

| Warranty Time | One Year or 1million shots |

English

English русский

русский Español

Español عربى

عربى

+86-15157625901 / 13706572756

+86-15157625901 / 13706572756 info@suncomold.com

info@suncomold.com  No.2 Gongxin Avenue, Beicheng Street, Huangyan, Taizhou, Zhejiang, China

No.2 Gongxin Avenue, Beicheng Street, Huangyan, Taizhou, Zhejiang, China