| 4L Two Parts Mobil Oil Cap Mould Feature |

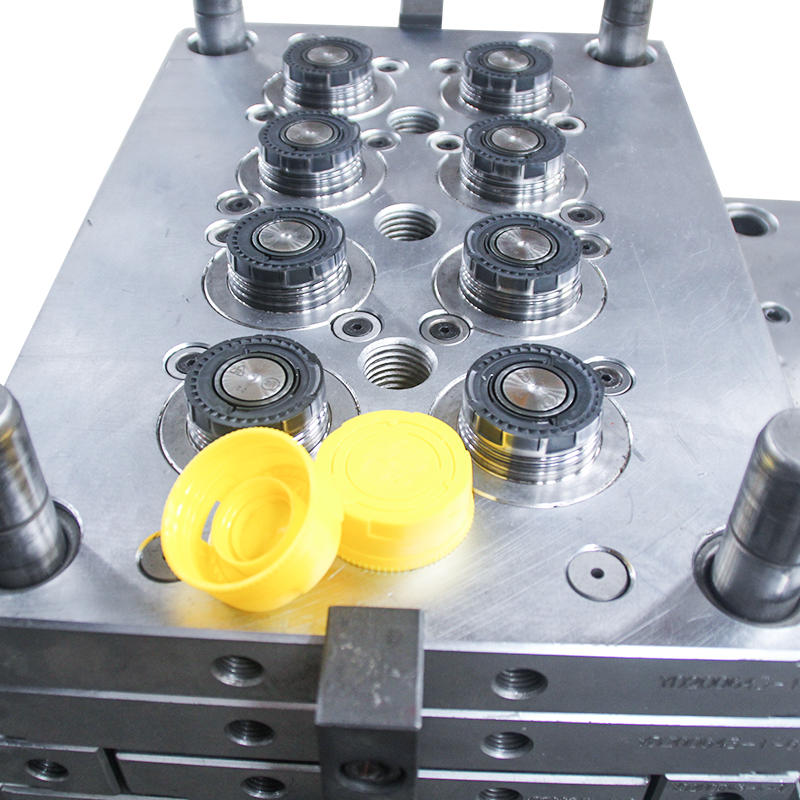

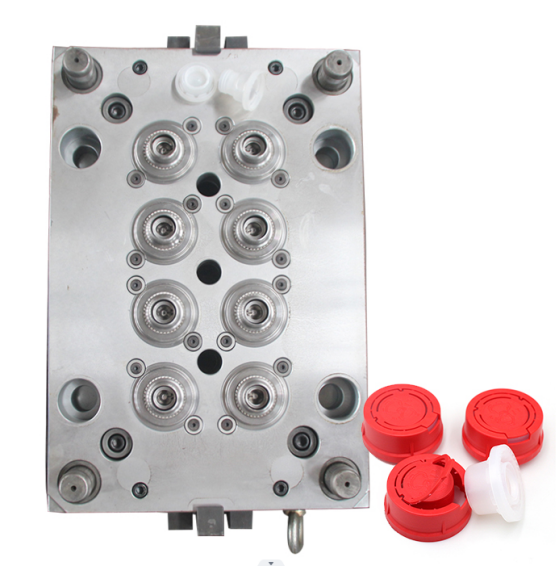

| 1. This Cap have two parts, outer cap and inner dropper |

| 2. Each cavity and core have independent cooling system for hot runner mould. |

| 3. Different Insert parts can be engraved for different oil company brand name on top of cap |

| 4. Stainless material have nice mirror hand polishing |

| 5. Each mould plates with electroplating treatment, which play a very long time rust prevention |

| 6. Runner system: Cold Runer, Half Hot Runner or Hot Runner system |

| 7. Hot runner brand: China advanced brand or imported hot runner system brand. |

8.Skilled Language in communication and experienced technical support

|

| Product Name |

4L Two Parts Mobil Oil Cap Mould |

| Core &Cavity Steel |

S136,FS636,632,ASSAB S136 |

|

| Mould base |

P20,4Cr13, Standard Mould Base |

| Steel hardness: |

HRC30-35 for base material. |

| HRC52-55 for core and cavity material. |

| HRC60 for ejector sleeve and other special parts. |

| Plastic material |

PP,PE,HDPE etc. |

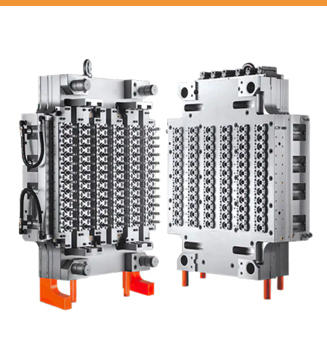

| Cavity Number |

1x4, 1x6, 1x8,1x12, 1x16, 1x24, 1x32, etc. |

| Injection System |

Pin gate, Submarine gate, Valve gate etc |

| Ejector System |

Unscrew by motor, stripper plate, ejector sleeve, ejector pin |

| Cycle Time |

Based on cap design |

| Delivery Time |

45-60 Days |

| Mould lifetime |

At least 3million Shots |

| Warranty Time |

One Year or 1million shots |

So when we open the outer cap, the inner cap could be come out which show the following picture:

So the most important for this EVA cap mould: the thickness of EVA spout cap need to be uniformed and when open, it is easy to be opened. And because the complicated parts, the cores has many parts and we must use the good material quality to ensure the mold life.

For the outer cap mould: it is also complicated and we must use hard heating treatment material to ensure the cap mold quality. The material of outer cap: we can use PP or PE material.

As I found that on the market, some market use PE material and some market use PP material.

Anyway, welcome for your kind inquiry for these kinds of plastic cap molds that we make many molds before and we have rich experience to make good and one time successful injection mold.

We have own standard mould frame for cap mould and handle mould, we make complete inspection on mould to ensure the structure consistence and spare parts standardized. In addition, we will do independent standardization test on mould cooling system and hot runner system. We are famous 4L Two Parts Mobil Oil Cap Mould suppliers and manufacturers in China. We take full range test and analysis on product size, appearance, injection techniques and Physical Parameter. The analysis includes mold flow analysis, mold ejection, cooling system, rationality of guide system, application of mold parts specification, customer's machine selection and application of special requirements. We also OEM/ODM 4L Two Parts Mobil Oil Cap Mould design & manufacturing.

English

English русский

русский Español

Español عربى

عربى

+86-15157625901 / 13706572756

+86-15157625901 / 13706572756 info@suncomold.com

info@suncomold.com  No.2 Gongxin Avenue, Beicheng Street, Huangyan, Taizhou, Zhejiang, China

No.2 Gongxin Avenue, Beicheng Street, Huangyan, Taizhou, Zhejiang, China